Foam Core vs. Wood Core: Which One is Best for Fiberglassing?

When building or repairing a fiberglass structure, choosing the right core material is crucial for strength, durability, and weight. Two of the most common core materials used in fiberglass construction are foam core and wood core. Each option has its own advantages and drawbacks, making it essential to understand their differences before deciding which one to use for your project.

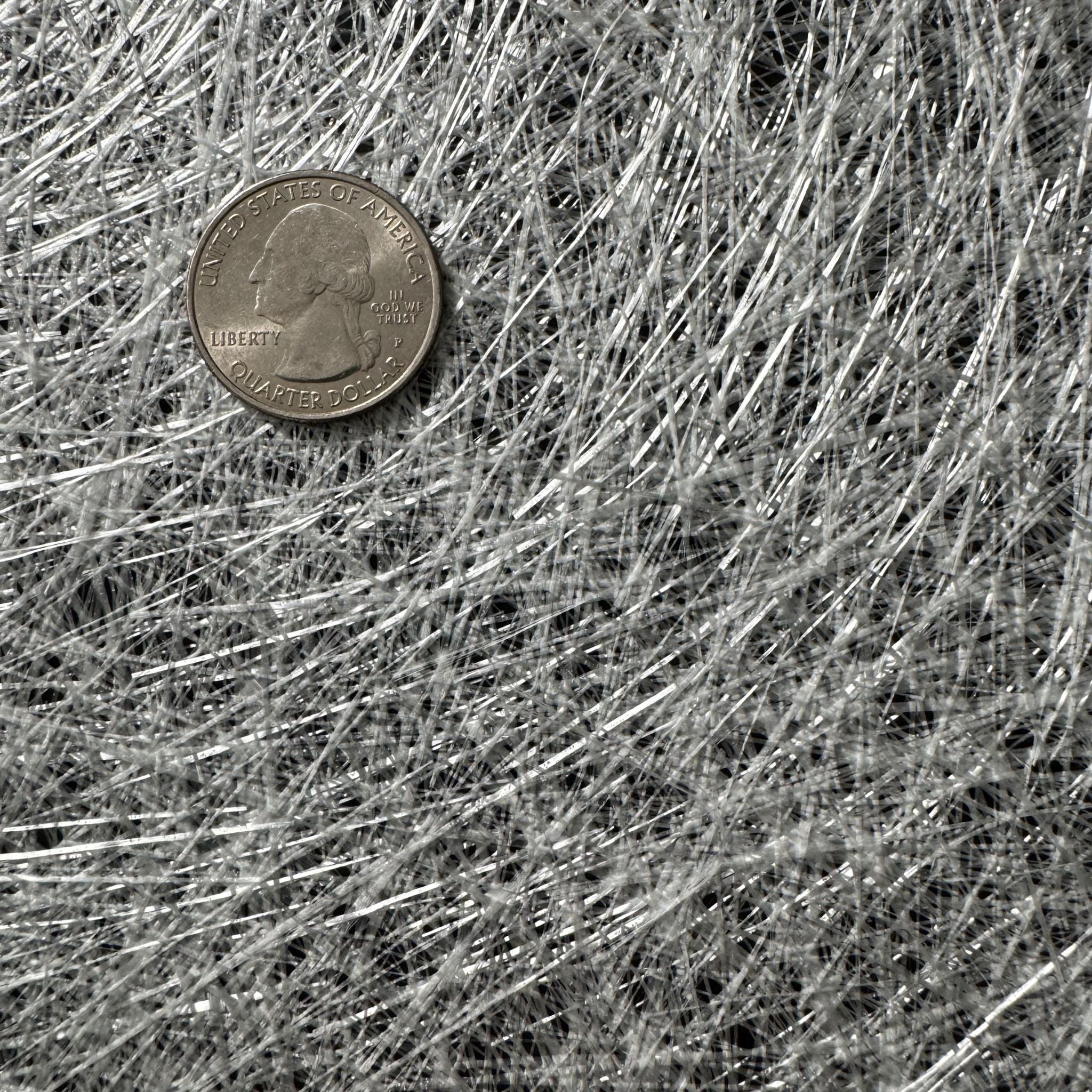

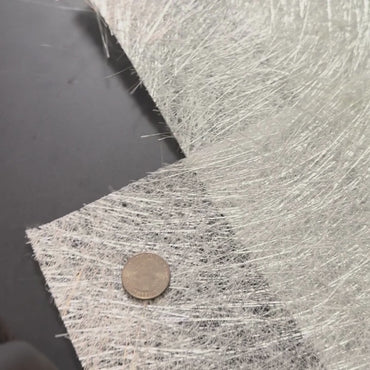

Foam Core: Lightweight and Rot-Resistant

Foam cores are made from materials such as polyurethane, PVC, and polystyrene, offering a lightweight and water-resistant option for fiberglass laminates.

Advantages of Foam Core:

- Waterproof: Unlike wood, foam will not absorb water, reducing the risk of rot and decay.

- Lightweight: Foam cores significantly reduce the weight of a structure, making them ideal for high-performance boats.

- Consistent Shape: Foam does not warp or shrink over time, maintaining structural integrity.

- Easy to Shape: Foam can be cut, sanded, and contoured easily, making it ideal for custom projects.

Disadvantages of Foam Core:

- Less Structural Strength: Foam is not as strong as wood, requiring additional fiberglass reinforcement for comparable durability.

- Higher Cost: Quality marine foam cores can be more expensive than wood alternatives.

- Compression Issues: If not properly laminated, foam can compress under high loads, leading to failure.

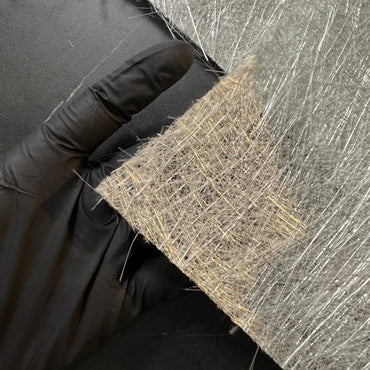

Wood Core: Strength and Affordability

Wood cores, commonly made from marine plywood, balsa, or Douglas fir, provide excellent strength and rigidity.

Advantages of Wood Core:

- High Strength: Wood has a superior load-bearing capacity compared to foam, making it ideal for structural applications.

- Affordable: Marine plywood and balsa are often more cost-effective than high-quality foam cores.

- Good Bonding with Fiberglass: Wood has excellent adhesion properties with resin and fiberglass, creating a strong, durable laminate.

Disadvantages of Wood Core:

- Water Absorption: If not properly sealed, wood can absorb water, leading to rot and degradation over time.

- Heavier Weight: Wood cores add more weight compared to foam, which can affect boat performance.

- Potential for Warping: Wood can expand, shrink, or warp with temperature and moisture changes if not properly protected.

Which One Should You Choose?

The best core material depends on your project’s needs:

- Choose Foam Core if you prioritize weight savings, water resistance, and ease of shaping for non-structural or performance applications.

- Choose Wood Core if you need superior strength, durability, and cost-effectiveness for structural applications like boat transoms, decks, and bulkheads.

For high-quality fiberglassing materials, foam cores, and marine plywood, check out Boat Suppliers for everything you need to get the job done right!

Prev post

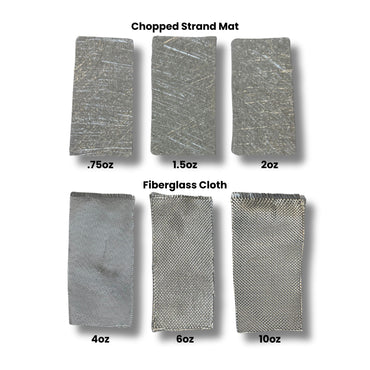

Best Fiberglass Cloth for Boat Floors

Updated on 22 March 2025

Next post

Useful Tips for Working with Fiberglass Mat

Updated on 20 March 2025