How to Properly Fiberglass a Boat Hull for Maximum Durability

Fiberglassing a boat hull is a crucial process that ensures strength, water resistance, and longevity. Whether you're building a new boat or repairing an existing hull, using the right techniques and materials will help you achieve a professional-grade finish. Below, we’ll guide you through the essential steps to fiberglass a boat hull for maximum durability.

Step 1: Gather Your Materials

Before you start, make sure you have all the necessary materials:

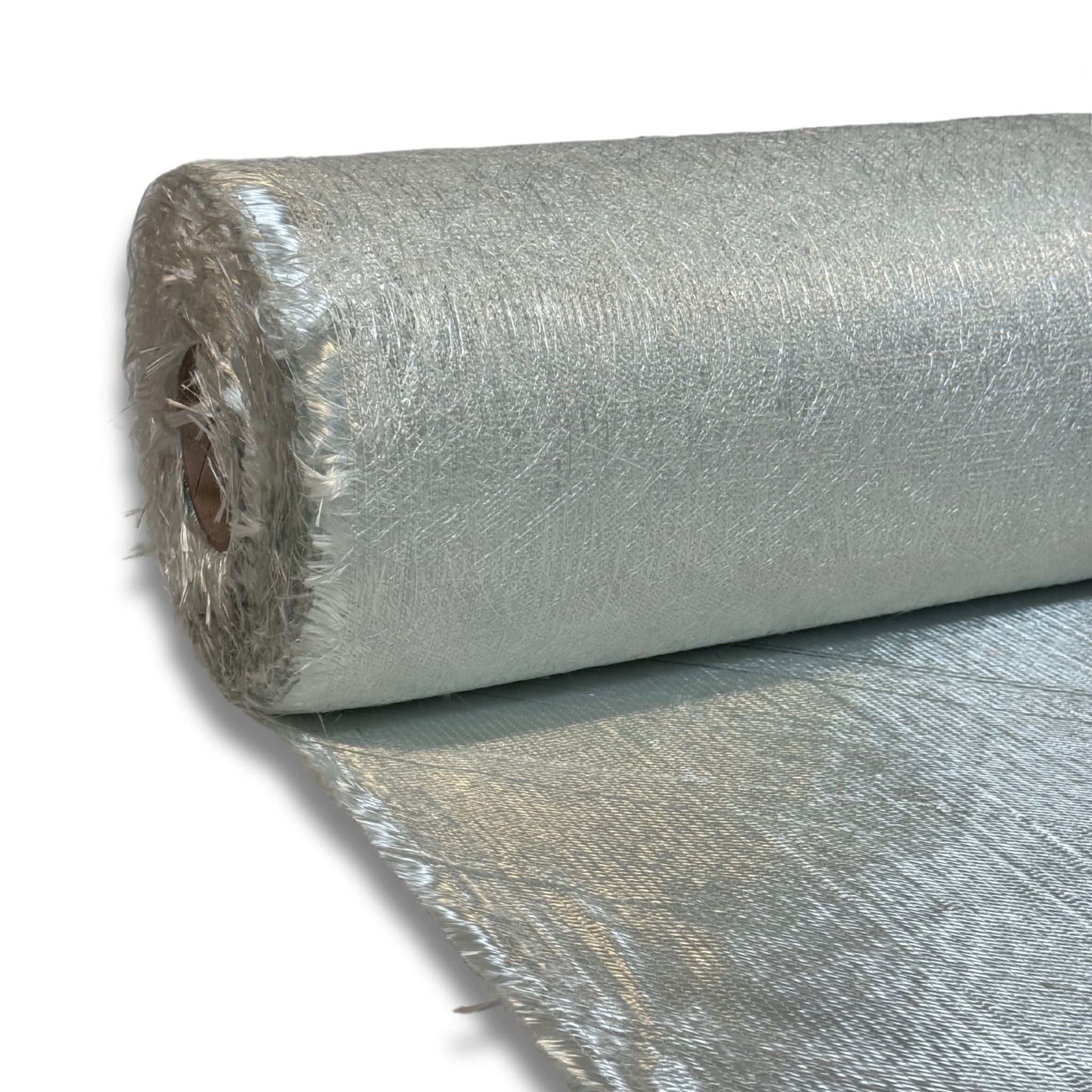

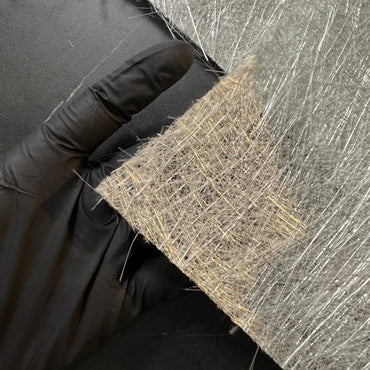

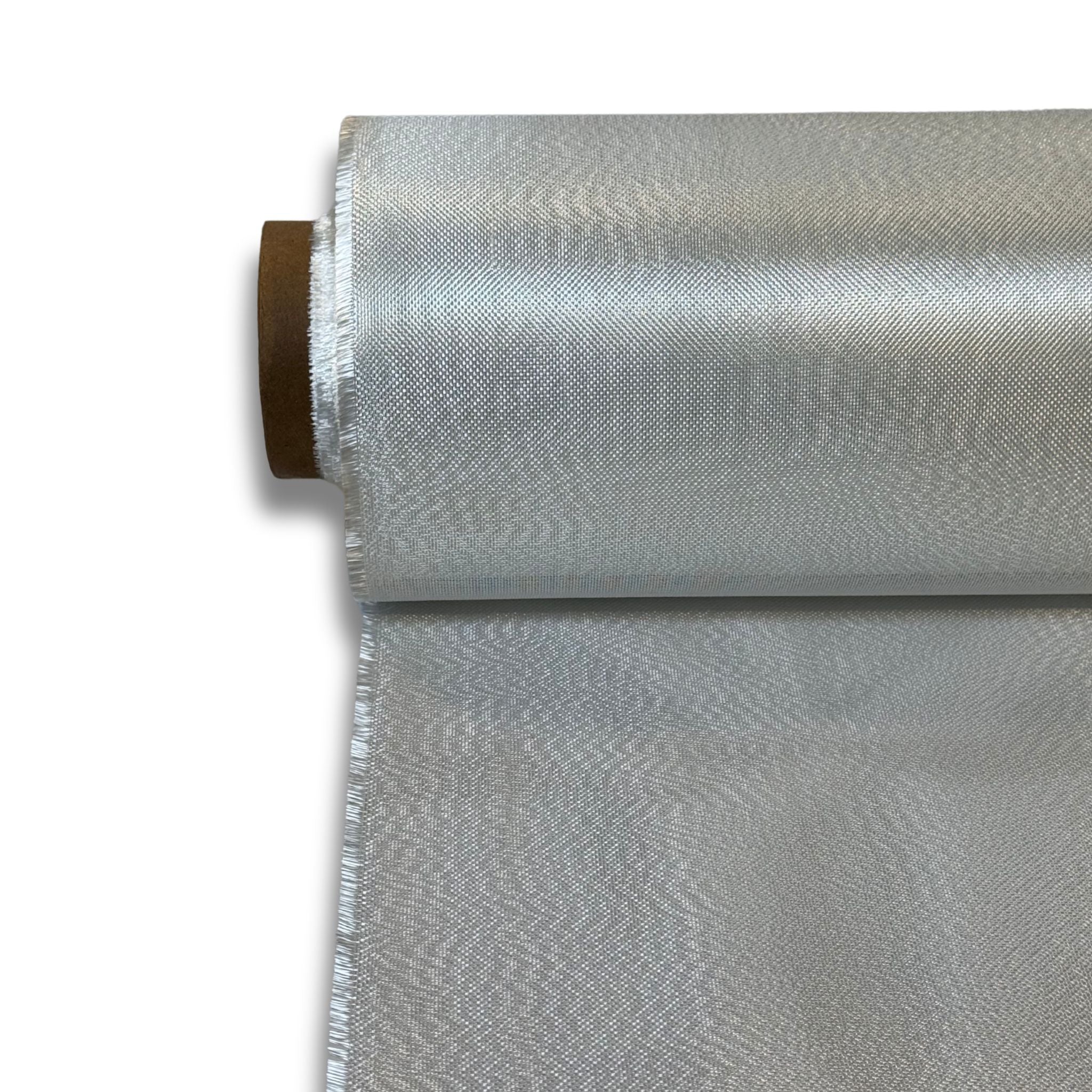

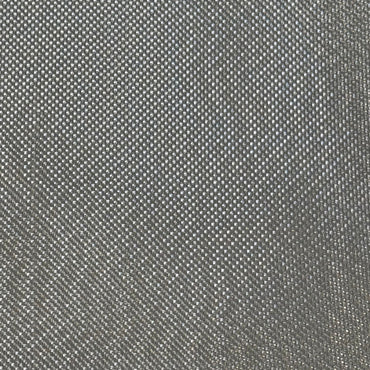

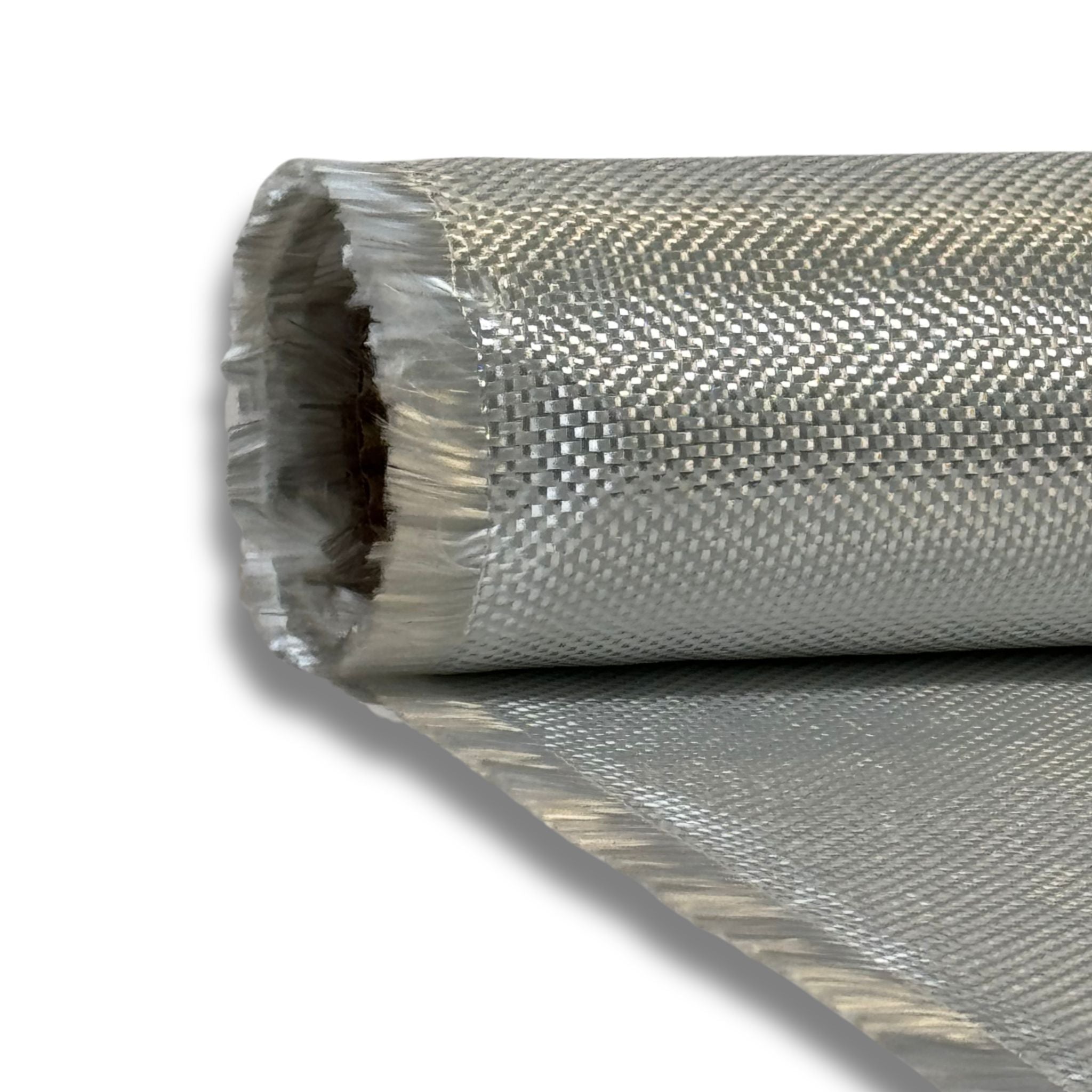

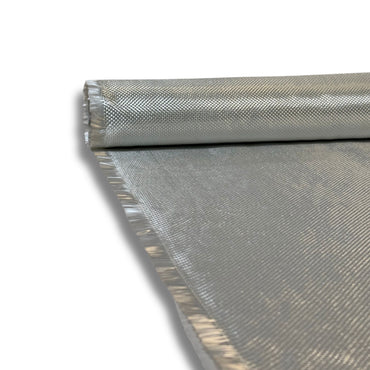

- Fiberglass cloth or mat – Choose between woven cloth for strength or chopped strand mat for bulk.

- Resin – Polyester, vinyl ester, or epoxy, depending on your needs.

- Hardener/Catalyst – Required to initiate resin curing.

- Acetone – For cleaning tools and surfaces.

- Sandpaper (60-120 grit) – For surface preparation and finishing.

- Rollers and Brushes – To apply resin and remove air bubbles.

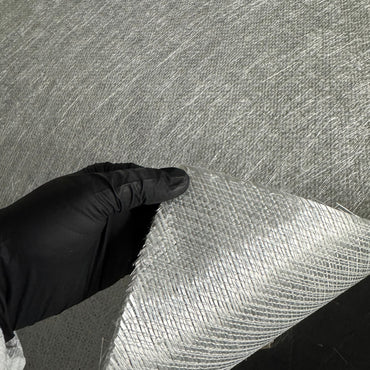

- Protective Gear – Gloves, respirator, and safety glasses.

Step 2: Prepare the Hull Surface

Proper surface preparation is essential for adhesion:

- Clean the hull – Remove dirt, grease, and old paint using acetone or marine cleaner.

- Sand the surface – Rough up the area with 60-80 grit sandpaper to improve resin bonding.

- Check for damage – Repair any cracks, holes, or weak spots before applying fiberglass.

- Mask off areas – Protect surrounding surfaces with masking tape and plastic sheeting.

Step 3: Cutting and Layering Fiberglass

- Measure and Cut – Pre-cut fiberglass cloth or mat to fit the hull area.

- Dry Fit First – Lay the material on the hull to check for proper placement before applying resin.

- Layering Plan – Use multiple layers, starting with lighter fiberglass and adding thicker layers for reinforcement.

Step 4: Mixing and Applying Resin

- Mix Resin and Hardener – Follow the manufacturer’s ratio for correct curing.

- Apply the First Layer – Brush or roll a thin layer of resin onto the hull.

- Lay Fiberglass Over Resin – Gently place the fiberglass material onto the wet resin.

- Saturate the Fiberglass – Use a roller to evenly distribute resin, ensuring no dry spots.

- Remove Air Bubbles – Roll out any trapped air pockets to avoid weak spots.

- Repeat as Needed – Add multiple layers, letting each partially cure before adding the next.

Step 5: Curing and Finishing

- Allow Full Cure – Follow the recommended curing time for your resin type.

- Sand the Surface – Use 80-120 grit sandpaper for a smooth finish.

- Apply Gelcoat or Paint – Seal and protect the fiberglass with a durable marine coating.

- Final Inspection – Check for imperfections and apply touch-ups if necessary.

Final Thoughts

Properly fiberglassing a boat hull ensures it remains strong, watertight, and resistant to wear for years to come. By following these steps and using high-quality materials, you can achieve a professional and durable finish.

Looking for top-quality materials? We got you covered with fiberglass, resins, and fiberglass tools? Visit our Fiberglass & Carbon

Prev post

How to Fix EPS Epoxy Surfboard

Updated on 30 June 2025

Next post

Understanding Fiberglass Weave Patterns and Their Uses

Updated on 10 April 2025