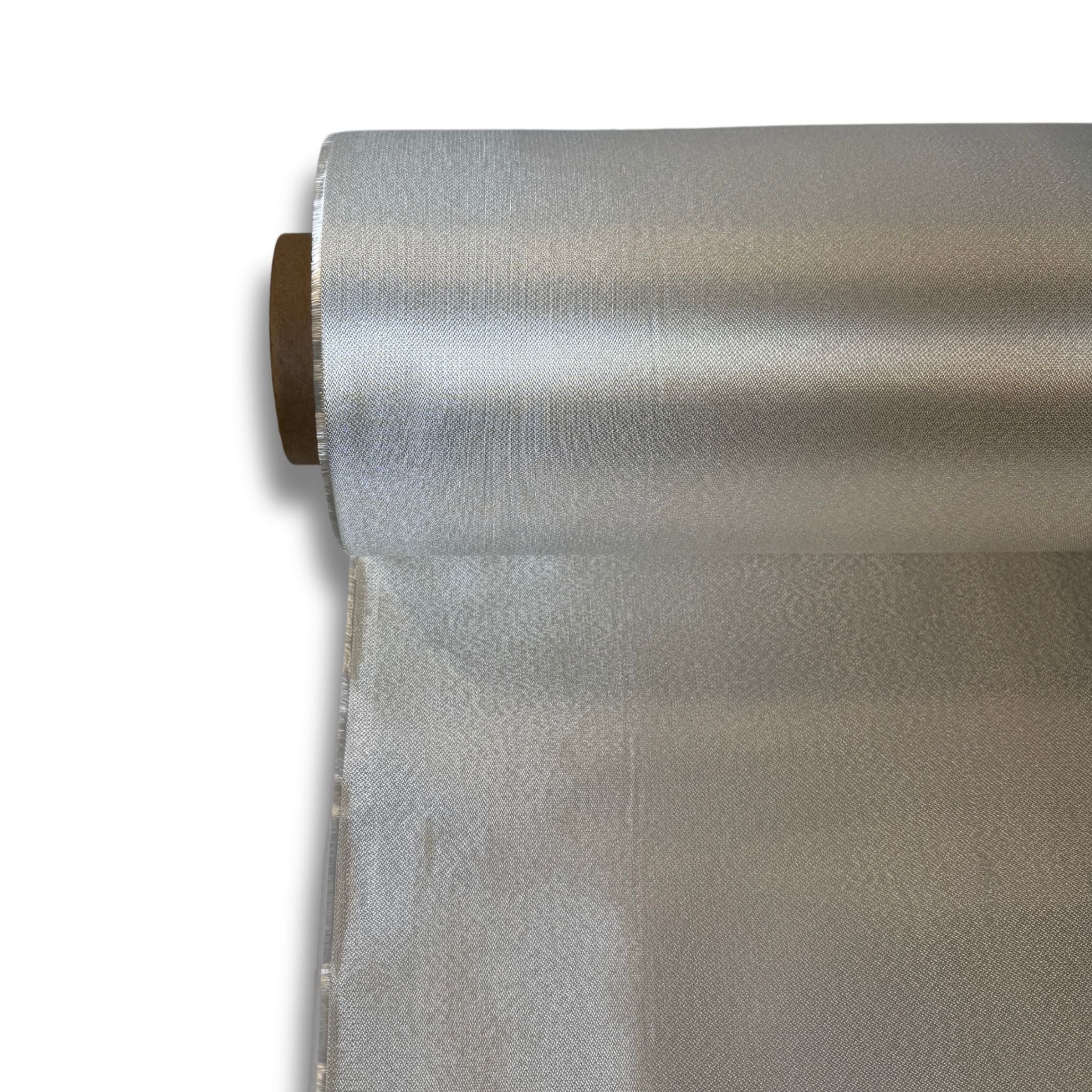

How Is Fiberglass Cloth Made?

Fiberglass cloth is a vital material in the world of boating, prized for its strength, durability, and resistance to corrosion. Whether you're building a custom hull, reinforcing a structure, or making repairs, chances are fiberglass cloth is part of the equation. But how is this essential material made? In this post, we’ll take a deep dive into how fiberglass cloth is created—from raw materials to the rolls you use on your boat.

What Is Fiberglass Cloth?

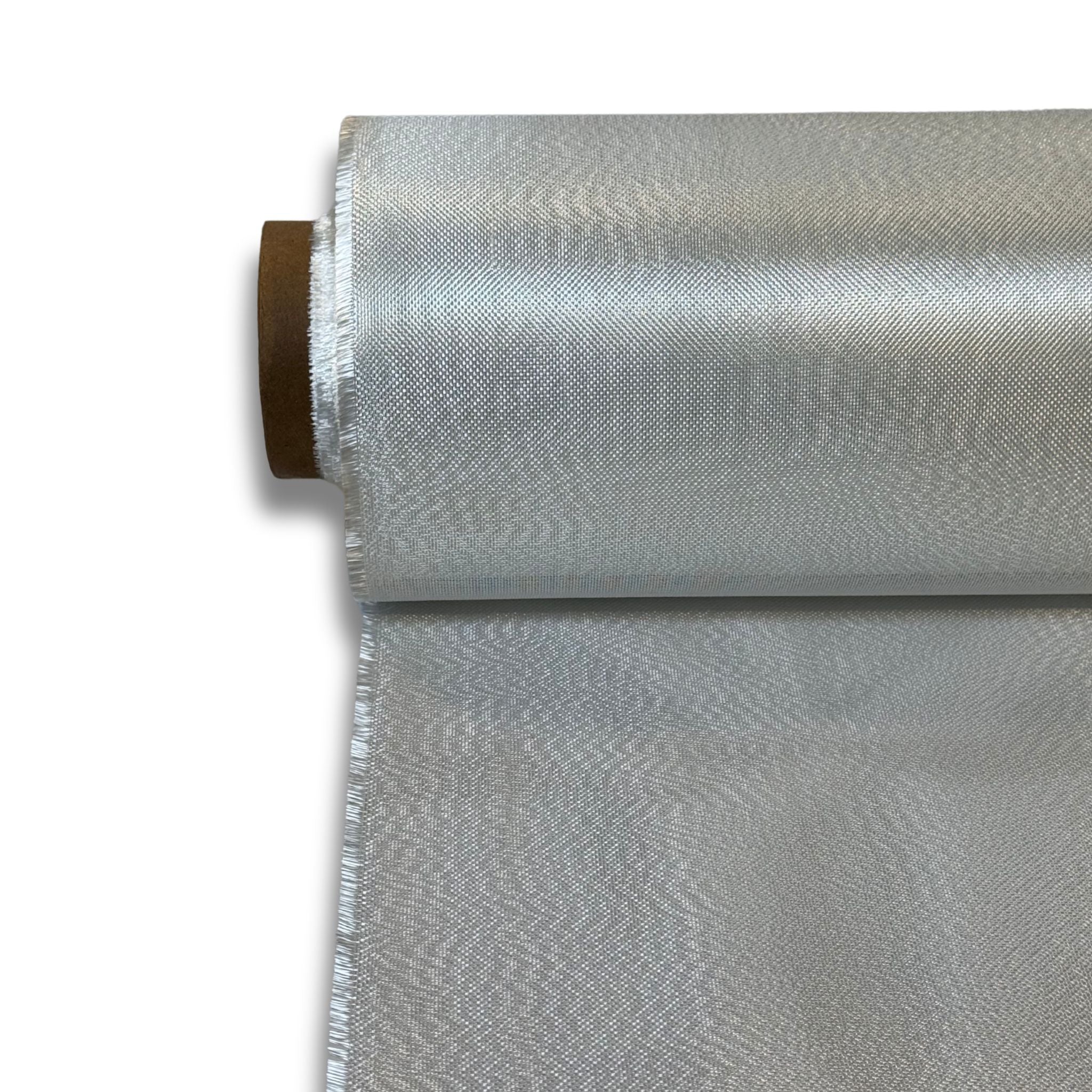

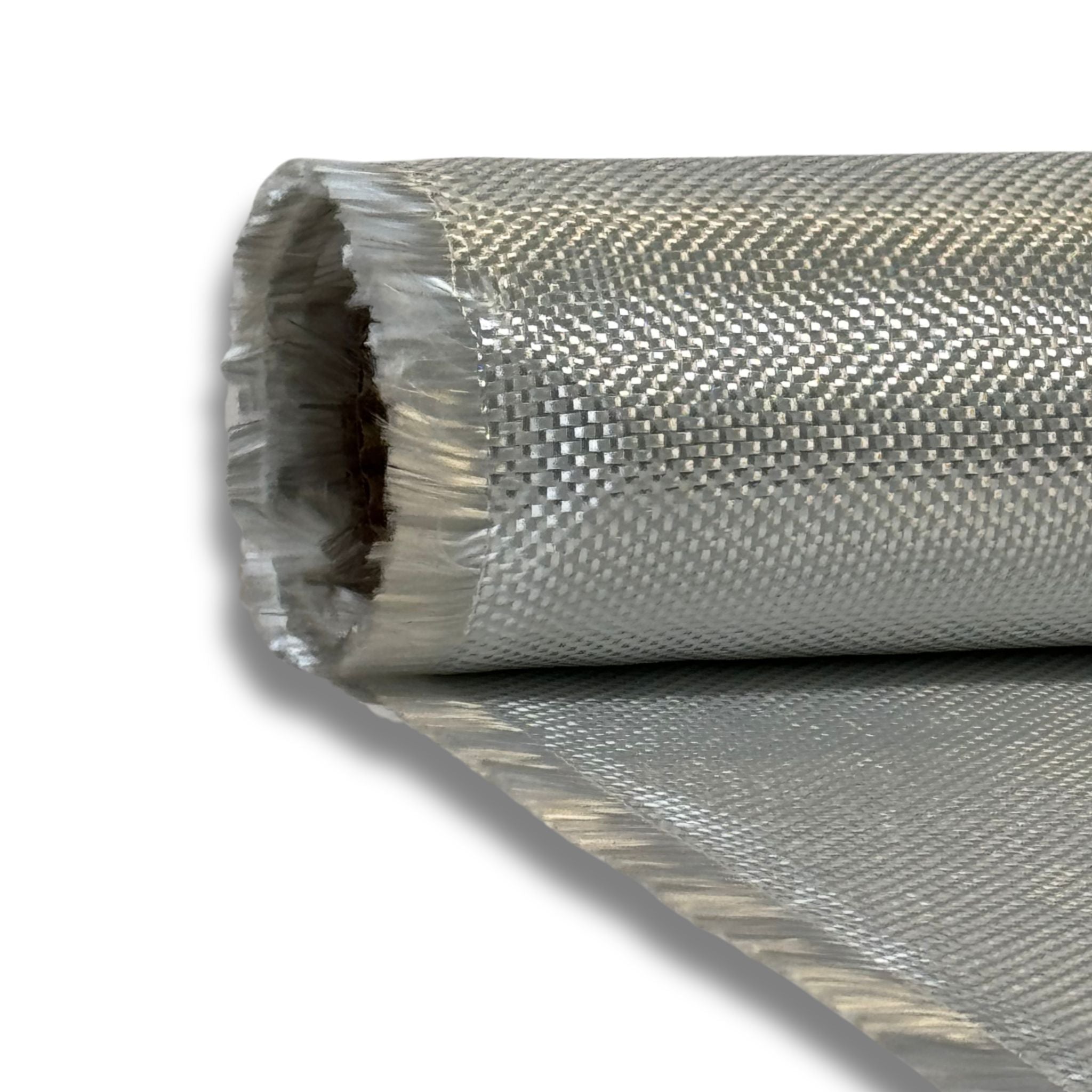

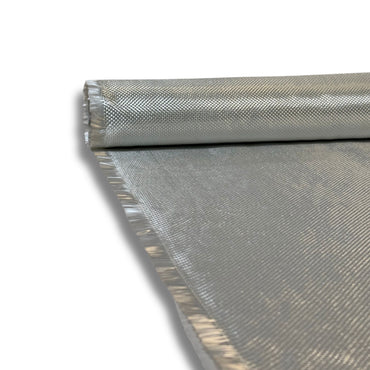

Fiberglass cloth is a woven fabric made from glass fibers. It's commonly used in boat building, surfboard shaping, automotive projects, and even aerospace manufacturing due to its lightweight strength and resistance to water, chemicals, and fire.

The cloth is typically paired with resin (such as epoxy or polyester) to form a solid, durable composite structure that’s ideal for marine environments.

Step 1: Melting Raw Materials

The process starts with raw materials like silica sand, limestone, and other minerals. These are melted together in a furnace at extremely high temperatures—typically around 2,500°F (1,370°C). This produces molten glass.

Step 2: Fiberizing the Glass

Once the glass is molten, it’s extruded through tiny holes in a device called a bushing. As the glass is pulled through these holes, it forms ultra-fine filaments, each only a few microns thick. These fibers are cooled rapidly and coated with a chemical binder to enhance adhesion and durability.

Step 3: Gathering the Fibers

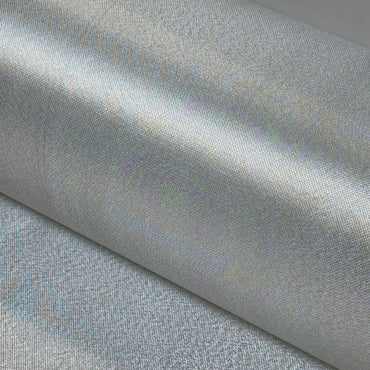

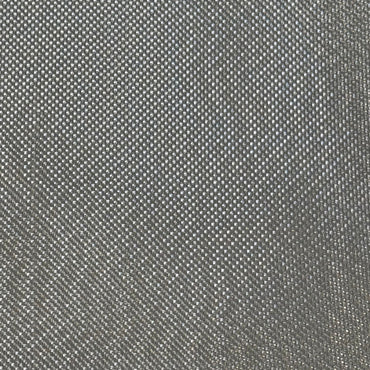

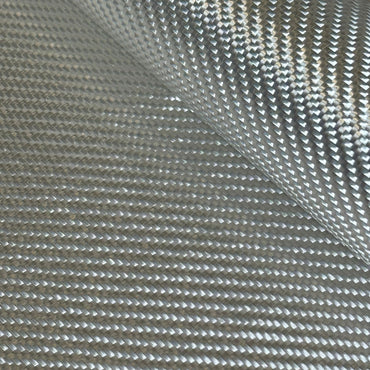

The fine strands are then gathered into bundles called rovings. These rovings can be twisted or left untwisted, depending on the desired characteristics of the final cloth. The type of weave and fiber pattern you choose—like plain weave, twill, or satin—will influence the flexibility, strength, and finish of your final product.

Step 4: Weaving the Cloth

The rovings are loaded onto looms and woven into fabric using traditional textile weaving methods. Different weaving patterns produce different grades of fiberglass cloth, each with unique properties tailored for various applications. For instance, a plain weave offers excellent stability and strength, while a satin weave is more flexible and conforms better to curves.

Step 5: Finishing

After weaving, the fiberglass cloth may go through additional treatments to improve compatibility with specific resins or to meet certain performance standards. It is then cut, rolled, and packaged—ready to ship to boat builders, repair shops, and DIYers around the world.

Why It Matters for Boaters

Fiberglass cloth is at the heart of many boat construction and repair projects. It provides the reinforcement needed to create strong hulls, decks, and structural components. Knowing how it’s made gives you better insight into the materials you're working with and helps you choose the right type for your specific marine application.

Looking to stock up for your next project?

Check out our full selection of fiberglass and resins—everything you need for top-quality repairs and custom builds.

Whether you're building a boat from scratch or tackling a fiberglass repair, understanding how fiberglass cloth is made helps you get the job done right—with strength, precision, and confidence on the water.

Prev post

Sanding and Fairing Techniques for Fiberglass Finishing

Updated on 09 August 2025

Next post

What's the Difference Between 2x2 Twill and Plain Weave Carbon Fiber?

Updated on 06 July 2025