Vacuum Bagging Guide

Vacuum bagging is a powerful laminating method that uses atmospheric pressure to evenly clamp composite materials while they cure. This technique enables stronger, lighter laminates and is widely used in boatbuilding, aerospace, automotive, and DIY applications.

What Is Vacuum Bagging?

Vacuum bagging uses a vacuum pump to remove air from a sealed envelope containing your laminate. The resulting pressure difference clamps all layers evenly, ensuring a void-free bond with minimal resin and maximum fiber content.

Benefits of Vacuum Bagging

- Even pressure distribution: Eliminates uneven force from clamps or staples.

- Superior bond quality: Less resin, fewer voids, stronger adhesion.

- Lightweight parts: Improves resin-to-fiber ratio.

- Complex shapes: Works with simple or curved molds.

- Efficient & scalable: Ideal for small repairs to full hull laminations.

Vacuum Bagging Equipment Checklist

-

Vacuum pump

- Sized to your project (pressure and flow).

- Key specs: Vacuum pressure (inHg) & air volume (CFM).

-

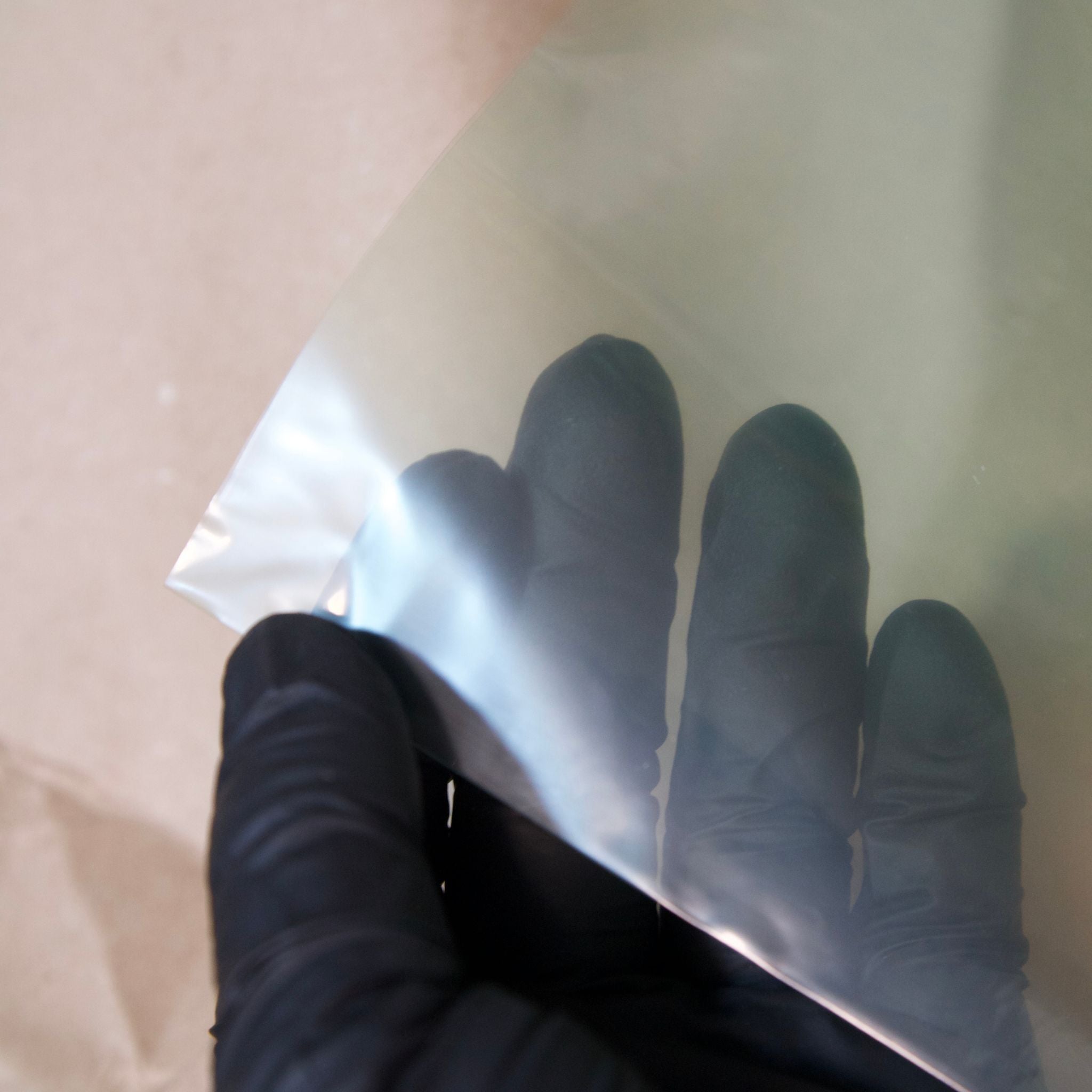

Vacuum bag film

- Heat-resistant plastic (e.g., nylon) that forms the vacuum envelope.

- Shop vacuum bagging materials

- Mastic sealant: Sticky tape to create airtight seals between mold and bag.

- Release fabric (peel ply): Prevents breather from sticking; removes cleanly post-cure.

- Perforated film (optional): Regulates resin bleed-through.

- Breather fabric: Lets air reach the vacuum port; absorbs excess resin.

- Vacuum lines, valves & trap: Connect pump to bag; keeps epoxy out of the pump.

- Vacuum gauge: Monitor vacuum during cure. Typical target: 12–25 inHg.

Mold Types

- Flat mold: Smooth, sealed worktable surface.

- Curved mold: Built from plugs (positive forms) using fiberglass/epoxy.

- Envelope bagging: Entire mold inside the bag—ideal for small or thin parts.

Step-by-Step: Vacuum Bag Laminating

Example: Laminating a Fiberglass Rudder

-

Prepare the mold

- Clean and wax mold surface.

- Apply mold release.

- Optional: apply epoxy gelcoat.

-

Lay up the laminate

- Wet out fiberglass layers and place in mold.

- Add core material if needed.

- Wet out additional layers as required.

-

Add release layers

- Lay peel ply.

- Optionally add perforated film (useful at higher vacuum levels or long open times).

-

Add breather and vacuum bag

- Lay breather fabric on top.

- Drape vacuum bag film and seal edges with mastic.

-

Insert vacuum port and gauge

- Puncture a small hole in the bag for the port.

- Place extra breather under the port to prevent epoxy suction.

-

Apply vacuum

- Start the pump and watch the gauge.

- Check for leaks around seals and folds.

- Maintain vacuum until epoxy fully cures.

- Remove layers and demold

- Peel off bag, breather, and release film.

- Pry laminate from mold with plastic wedges.

- Trim, sand, and finish.

Tips for Better Results

- Always test your system before adding epoxy.

- Avoid bridging—ensure fabric reaches into all corners.

- Use perforated film for high vacuum or long open-time epoxies.

- Don’t overtighten vacuum—avoid starving the laminate of resin.

- Post-curing: Some projects require heat to reach final strength (check resin specs).

Applications Beyond Boats

- Rudders, centerboards

- Deck panels

- Carbon-fiber components

- Cold-molded hulls

- Lightweight hatches or beams

Troubleshooting Vacuum Bagging

- Leaks? Check mastic, folds, and port seals.

- Low vacuum? Confirm pump CFM and bag integrity.

- Voids? Watch for bridging; ensure proper wet-out and compaction.

Ready to Start Vacuum Bagging?

Explore high-quality materials and equipment for your next project:

👉 Vacuum Bagging Supplies at Boat Suppliers

Prev post

How Is Fiberglass Chopped Strand Mat Made?

Updated on 15 August 2025

Next post

What is Epoxy Resin? A Complete Guide for Beginners

Updated on 10 August 2025