Tissus spéciaux

-

Fournisseur :Boat Suppliers

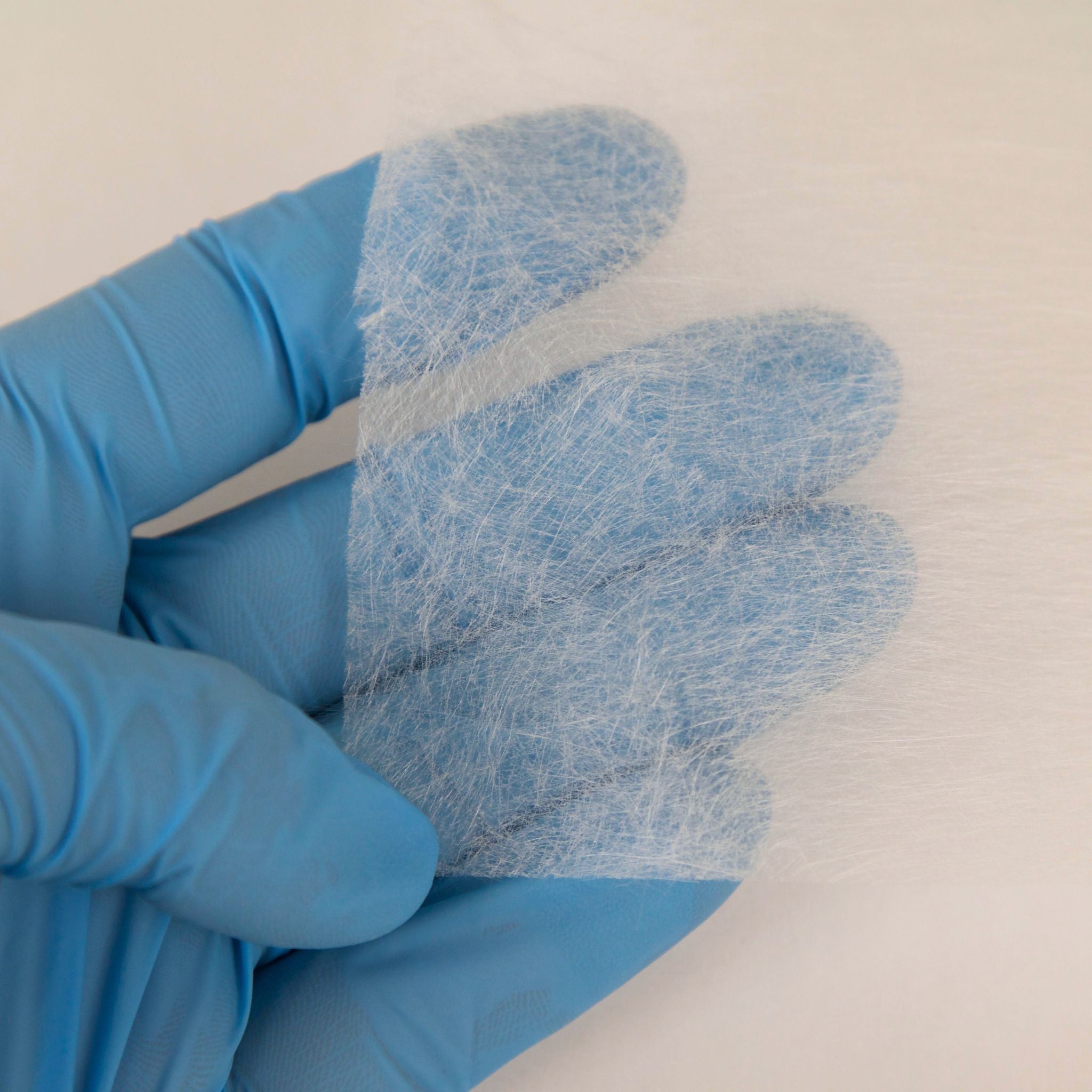

Voile de surface

Épaisseur de 10 MIL - largeur de 38 po Utilisé pour empêcher l'impression sur les surfaces du moule...Prix habituel $2.45 USDPrix promotionnel $2.45 USD Prix habituelPrix unitaire par -

Fournisseur :Boat Suppliers

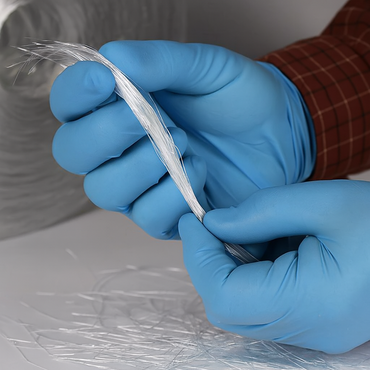

Arme à feu Roving - Boîte de 39,5 lb

Le Gun Roving est un fil continu de fibre de verre, conçu principalement pour être utilisé avec des...Prix habituel $98.50 USDPrix promotionnel $98.50 USD Prix habituelPrix unitaire par

Tissus spéciaux

Découvrez des tissus spécialisés comme le voile de surface et le roving pour les projets marins et composites. Idéals pour les couches de finition, la résistance et l'écoulement de la résine dans les applications en fibre de verre.